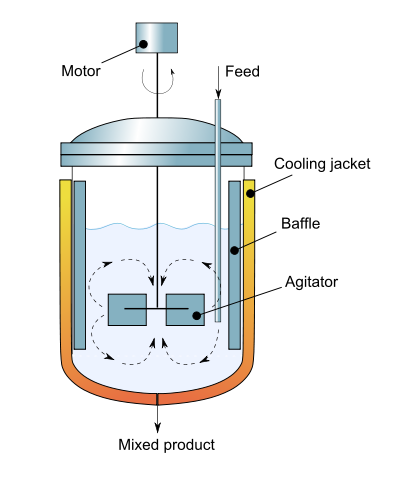

A task common to many control projects is to simulate the PID control of a nonlinear process. This notebook demonstrates the simulation of PID for an exothermic stirred tank reactor where the objective is to control the reactor temperature through manipulation of cooling water through the reactor cooling jacket.

(Diagram By Daniele Pugliesi - Own work, CC BY-SA 3.0, Link)

The model consists of nonlinear mole and energy balances on the contents of the well-mixed reactor.

\begin{align*} V\frac{dc}{dt} & = q(c_f - c )-Vk(T)c \\ \rho C_p V\frac{dT}{dt} & = wC_p(T_f - T) + (-\Delta H_R)Vk(T)c + UA(T_c-T) \end{align*}where $c$ is the reactant concentration, $T$ is the reactor temperature, and $T_c$ is the cooling jacket temperature. The model is adapted from example 2.5 from Seborg, Edgar, Mellichamp and Doyle (SEMD), parameters defined and given in the table below.

The temperature in the cooling jacket is manipulated by the cooling jacket flow, $q_c$, and governed by the energy balance

\begin{align*} \rho C_p V_c\frac{dT_c}{dt} & = \rho C_p q_c(T_{cf}-T_c) + UA(T - T_c) \end{align*}Normalizing the equations to isolate the time rates of change of $c$, $T$, and $T_c$ give

\begin{align*} \frac{dc}{dt} & = \frac{q}{V}(c_f - c)- k(T)c\\ \frac{dT}{dt} & = \frac{q}{V}(T_i - T) + \frac{-\Delta H_R}{\rho C_p}k(T)c + \frac{UA}{\rho C_pV}(T_c - T)\\ \frac{dT_c}{dt} & = \frac{q_c}{V_c}(T_{cf}-T_c) + \frac{UA}{\rho C_pV_c}(T - T_c) \end{align*}These are the equations that will be integrated below.

| Quantity | Symbol | Value | Units | Comments |

|---|---|---|---|---|

| Activation Energy | $E_a$ | 72,750 | J/gmol | |

| Arrehnius pre-exponential | $k_0$ | 7.2 x 1010 | 1/min | |

| Gas Constant | $R$ | 8.314 | J/gmol/K | |

| Reactor Volume | $V$ | 100 | liters | |

| Density | $\rho$ | 1000 | g/liter | |

| Heat Capacity | $C_p$ | 0.239 | J/g/K | |

| Enthalpy of Reaction | $\Delta H_r$ | -50,000 | J/gmol | |

| Heat Transfer Coefficient | $UA$ | 50,000 | J/min/K | |

| Feed flowrate | $q$ | 100 | liters/min | |

| Feed concentration | $c_{A,f}$ | 1.0 | gmol/liter | |

| Feed temperature | $T_f$ | 350 | K | |

| Initial concentration | $c_{A,0}$ | 0.5 | gmol/liter | |

| Initial temperature | $T_0$ | 350 | K | |

| Coolant feed temperature | $T_{cf}$ | 300 | K | |

| Nominal coolant flowrate | $q_c$ | 50 | L/min | primary manipulated variable |

| Cooling jacket volume | $V_c$ | 20 | liters |

%matplotlib inline

import matplotlib.pyplot as plt

import numpy as np

from scipy.integrate import odeint

import seaborn as sns

sns.set_context('talk')

Ea = 72750 # activation energy J/gmol

R = 8.314 # gas constant J/gmol/K

k0 = 7.2e10 # Arrhenius rate constant 1/min

V = 100.0 # Volume [L]

rho = 1000.0 # Density [g/L]

Cp = 0.239 # Heat capacity [J/g/K]

dHr = -5.0e4 # Enthalpy of reaction [J/mol]

UA = 5.0e4 # Heat transfer [J/min/K]

q = 100.0 # Flowrate [L/min]

Cf = 1.0 # Inlet feed concentration [mol/L]

Tf = 300.0 # Inlet feed temperature [K]

C0 = 0.5 # Initial concentration [mol/L]

T0 = 350.0; # Initial temperature [K]

Tcf = 300.0 # Coolant feed temperature [K]

qc = 50.0 # Nominal coolant flowrate [L/min]

Vc = 20.0 # Cooling jacket volume

# Arrhenius rate expression

def k(T):

return k0*np.exp(-Ea/R/T)

def deriv(X,t):

C,T,Tc = X

dC = (q/V)*(Cf - C) - k(T)*C

dT = (q/V)*(Tf - T) + (-dHr/rho/Cp)*k(T)*C + (UA/V/rho/Cp)*(Tc - T)

dTc = (qc/Vc)*(Tcf - Tc) + (UA/Vc/rho/Cp)*(T - Tc)

return [dC,dT,dTc]

The given reaction is highly exothermic. If operated without cooling, the reactor will reach an operating temperature of 500K which leads to significant pressurization, a potentially hazardous condition, and possible product degradation.

The purpose of this first simulation is to determine the cooling water flowrate necessary to maintain the reactor temperature at an acceptable value. This simulation shows the effect of the cooling water flowrate, $q_c$, on the steady state concentration and temperature of the reactor. We use the scipy.integrate function odeint to create a solution of the differential equations for entire time period.

# visualization

def plotReactor(t,X):

plt.subplot(1,2,1)

plt.plot(t,X[:,0])

plt.xlabel('Time [min]')

plt.ylabel('gmol/liter')

plt.title('Reactor Concentration')

plt.ylim(0,1)

plt.subplot(1,2,2)

plt.plot(t,X[:,1])

plt.xlabel('Time [min]')

plt.ylabel('Kelvin');

plt.title('Reactor Temperature')

plt.ylim(300,520)

Once the visualization code has been established, the actual simulation is straightforward.

IC = [C0,T0,Tcf] # initial condition

t = np.linspace(0,8.0,2000) # simulation time grid

qList = np.linspace(0,200,11)

plt.figure(figsize=(16,4)) # setup figure

for qc in qList: # for each flowrate q_c

X = odeint(deriv,IC,t) # perform simulation

plotReactor(t,X) # plot the results

plt.legend(qList)

<matplotlib.legend.Legend at 0x1051a5c88>

The results clearly show a strongly nonlinear behavior for cooling water flowrates in the range from 140 to 160 liters per minute. Here we expand on that range to better understand what is going on.

IC = [C0,T0,Tcf] # initial condition

t = np.linspace(0,8.0,2000) # simulation time grid

qList = np.linspace(153,154,11)

plt.figure(figsize=(16,4)) # setup figure

for qc in qList: # for each flowrate q_c

X = odeint(deriv,IC,t) # perform simulation

plotReactor(t,X) # plot the results

plt.legend(qList)

<matplotlib.legend.Legend at 0x11508b438>

There's a clear bifurcation when operated without feedback control. At cooling flowrates less than 153.7 liters/minute, the reactor goes to a high conversion steady state with greater than 95% conversion and a reactor temperature higher than about 410K. Coolant flowrates less than 153.8 liters/minute result in uneconomic operation at low conversion.

For the remainder of this notebook, our objective will be to achieve stable operation of the reactor at a high conversion steady state but with an operating temperature below 400 K, an operating condition that does not appear to be possible without feedback control.

Introducing feedback control requires a change in the simulation strategy.

The new approach will be to break the simulation interval up into small time steps of length $dt$. At each breakpoint a PID control calculation will be performed, the coolant flow updated, then odeint will be used to simulate the reactor up to the next breakpoint.

The following cell demontrates the simulation strategy assuming a constant coolant flowrate. Note the use of Python lists to log simulation values for later plotting.

# set initial conditions and cooling flow

IC = [C0,T0,Tcf]

# do simulation at fixed time steps dt

dt = 0.05

ti = 0.0

tf = 8.0

# create python list to log results

log = []

# start simulation

c,T,Tc = IC

qc = 153.8

for t in np.linspace(ti,tf,int((tf-ti)/dt)+1):

log.append([t,c,T,Tc,qc]) # log data for later plotting

c,T,Tc = odeint(deriv,[c,T,Tc],[t,t+dt])[-1] # start at t, find state at t + dt

def qplot(log):

log = np.asarray(log).T

plt.figure(figsize=(16,4))

plt.subplot(1,3,1)

plt.plot(log[0],log[1])

plt.title('Concentration')

plt.ylabel('moles/liter')

plt.xlabel('Time [min]')

plt.subplot(1,3,2)

plt.plot(log[0],log[2],log[0],log[3])

if 'Tsp' in globals():

plt.plot(plt.xlim(),[Tsp,Tsp],'r:')

plt.title('Temperature')

plt.ylabel('Kelvin')

plt.xlabel('Time [min]')

plt.legend(['Reactor','Cooling Jacket'])

plt.subplot(1,3,3)

plt.plot(log[0],log[4])

plt.title('Cooling Water Flowrate')

plt.ylabel('liters/min')

plt.xlabel('Time [min]')

plt.tight_layout()

SS = log[-1]

qplot(log)

Proportional-Integral-Derivative (PID) control is the workhorse of the process control industry. In standard form, the PID algorithm would be written

$$q_c(t) = \bar{q}_c - K_c\left[(T_{sp}-T) + \frac{1}{\tau_I}\int_0^t (T_{sp}-T)dt' + \tau_D\frac{d(T_{sp}-T)}{dt} \right]$$For the control reactor temperature, note the controller is 'direct-acting' such that a positive excursion of the reactor temperature $T$ above the setpoint $T_{sp}$ is compensated by an increase in coolant flow, and vice-versa. Thus a negative sign appears before the term $K_c$ contrary to the usual textbook convention for negative feedback control.

The practical implementation of PID control is generally facilitated by a number of modifications.

A common practice is to introduce an independent parameterization for each fo the P, I, and D terms. Rewriting, the control equation becomes

$$q_c(t) = \bar{q}_c - \left[k_P(T_{sp}-T) + k_I\int_0^t (T_{sp}-T)dt' + k_D\frac{d(T_{sp}-T)}{dt} \right]$$where

\begin{align*} k_P & = K_c \\ k_I & = \frac{K_c}{\tau_I} \\ k_D & = K_c\tau_D \end{align*}Step changes in setpoint $T_{sp}$ can produce undesired 'kicks' and 'bumps' if PID control is implemented directly using in standard form. It is common practice to introduce setpoint weighting factors for the proportional and derivative terms. This can be written as

$$q_c(t) = \bar{q}_c - \left[k_Pe_P(t) + k_I\int_0^t e_I(t')dt' + k_D\frac{e_D(t)}{dt} \right]$$where

\begin{align*} e_P(t) & = \beta T_{sp}(t) - T(t) \\ e_I(t) & = T_{sp}(t) - T(t) \\ e_D(t) & = \gamma T_{sp}(t) - T(t) \end{align*}Common practice is to set $\gamma = 0$ which eliminates derivative action based on change in the setpoint. This feature is sometimes called 'derivative on output'. This almost always a good idea in process control since it avoids the 'derivative kick' associated with a change in setpoint.

In practice, the term $\beta$ is generally tuned to meet the specific application requirements. In this case, where setpoint tracking is not a high priority, setting $\beta = 0$ is a reasonable starting point.

The simulation strategy adopted here requires a discrete time implementation of PID control. For a sampling time $dt$, the PID algorithm becomes

$$q_c(t_k) = \bar{q}_c - \left[k_Pe_P(t_k) + k_Idt\sum_0^{t_k} e_I(t_{k'}) + k_D\frac{e_D(t_k)-e_D(t_{k-1})}{dt} \right]$$Implementation is further streamlined by computing changes is $q_c(t_k)$

$$\Delta q_c(t_k) = q_c(t_k) - q_c(t_{k-1})$$Computing the differences

$$\Delta q_c(t_k) = -\left[k_P(e_P(t_k)-e_P(t_{k-1})) + k_I\ dt\ e_I(t_k) + k_D\frac{e_D(t_k) - 2e_D(t_{k-1}) + e_D(t_{k-2})}{dt}\right]$$A final consideration is that the coolant flows have lower and upper bounds of practical operation.

$$q_c = \max(q_{c,min},\max(q_{c,max},q_c)) $$# setpoint

Tsp = 390

# set initial conditions and cooling flow

IC = [C0,T0,Tcf]

# do simulation at fixed time steps dt

dt = 0.05

ti = 0.0

tf = 8.0

# control saturation

qc_min = 0 # minimum possible coolant flowrate

qc_max = 300 # maximum possible coolant flowrate

def sat(qc): # function to return feasible value of qc

return max(qc_min,min(qc_max,qc))

# control parameters

kp = 40

ki = 80

kd = 0

beta = 0

gamma = 0

# create python list to log results

log = []

# start simulation

c,T,Tc = IC

qc = 150

eP_ = beta*Tsp - T

eD_ = gamma*Tsp - T

eD__ = eD_

for t in np.linspace(ti,tf,int((tf-ti)/dt)+1):

# PID control calculations

eP = beta*Tsp - T

eI = Tsp - T

eD = gamma*Tsp - T

qc -= kp*(eP - eP_) + ki*dt*eI + kd*(eD - 2*eD_ + eD__)/dt

qc = sat(qc)

# log data and update state

log.append([t,c,T,Tc,qc])

c,T,Tc = odeint(deriv,[c,T,Tc],[t,t+dt])[-1] # start at t, find state at t + dt

# save data for PID calculations

eD__,eD_,eP_ = eD_,eD,eP

qplot(log)

In this example, PID control is used to stabilize an otherwise unstable steady state, thereby allowing the reactor to operate at temperature and conversion that would not be possible without control. The acheivable operating conditions are limited by the controller tuning and the limits on the available control action.

The following simulation provides for the interactive adjustment of reactor setpoint temperature and the proportional, integral, and derivative control gains. Adjust these in order to answer the following questions:

What is the minimum achieveable temperature setpoint for the reactor with conversion greater than 80%? What limits the ability to reduce the temperature setpoint even further?

Adjust the temperature setpoint to 420K. Adjust the controller gains for satisfactory closed-loop performance. Repeat the exercise for a setpoint of 390K. How is the behavior different? What happens when when the proportional gain is set too small? Explain what you see.

from ipywidgets import interact

IC = [C0,T0,Tcf]

def sim(Tsetpoint,kp,ki,kd):

global Tsp, qc

Tsp = Tsetpoint

# control parameters

beta = 0

gamma = 0

# create python list to log results

log = []

# start simulation

c,T,Tc = IC

qc = 150

eP_ = beta*Tsp - T

eD_ = gamma*Tsp - T

eD__ = eD_

for t in np.linspace(ti,tf,int((tf-ti)/dt)+1):

# PID control calculations

eP = beta*Tsp - T

eI = Tsp - T

eD = gamma*Tsp - T

qc -= kp*(eP - eP_) + ki*dt*eI + kd*(eD - 2*eD_ + eD__)/dt

qc = sat(qc)

# log data and update state

log.append([t,c,T,Tc,qc])

c,T,Tc = odeint(deriv,[c,T,Tc],[t,t+dt])[-1] # start at t, find state at t + dt

# save data for PID calculations

eD__ = eD_

eD_ = eD

eP_ = eP

qplot(log)

interact(sim,Tsetpoint = (360,420),kp = (0,80), ki=(0,160), kd=(0,10));

From this point on, this notebook describes the development of a PID control class that could be used in more complex simulations. Regard everything after this point as 'try at your own risk'!

Examples of PID Codes in Python:

Below we demonstrate the use of PIDsim, a python module that can be used to implement multiple PID controllers in a single simulation.

from PIDsim import PID

# reactor temperature setpoint

Tsp = 390

# set initial conditions and cooling flow

IC = [C0,T0,Tcf]

# do simulation at fixed time steps dt

tstart = 0

tstop = 8

tstep = 0.05

# configure controller. Creates a PID object.

reactorPID = PID(Kp=8,Ki=30,Kd=5,MVrange=(0,300),DirectAction=True)

c,T,Tc = IC # reactor initial conditions

qc = 150 # initial condition of the MV

for t in np.arange(tstart,tstop,tstep): # simulate from tstart to tstop

qc = reactorPID.update(t,Tsp,T,qc) # update manipulated variable

c,T,Tc = odeint(deriv,[c,T,Tc],[t,t+dt])[-1] # start at t, find state at t + dt

reactorPID.manual() # switch to manual model

T -= 10 # change process variable by -10 deg

for t in np.arange(t,t+1,tstep): # simulate for 1 minute

qc = reactorPID.update(t,Tsp,T,qc) # continue to update, SP tracks PV

c,T,Tc = odeint(deriv,[c,T,Tc],[t,t+dt])[-1] # start at t, find state at t + dt

reactorPID.auto() # switch back to auto mode

for t in np.arange(t,t+tstop,tstep): # integrate another tstop minutes

qc = reactorPID.update(t,Tsp,T,qc) # update MV

c,T,Tc = odeint(deriv,[c,T,Tc],[t,t+dt])[-1] # start at t, find state at t + dt

# plot controller log

reactorPID.plot() # plot controller log

# %load PIDsim.py

import matplotlib.pyplot as plt

import numpy as np

class PID:

""" An implementation of a PID control class for use in process control simulations.

"""

def __init__(self, name=None, SP=None, Kp=0.2, Ki=0, Kd=0, beta=1, gamma=0, MVrange=(0,100), DirectAction=False):

self.name = name

self.SP = SP

self.Kp = Kp

self.Ki = Ki

self.Kd = Kd

self.beta = beta

self.gamma = gamma

self.MVrange = MVrange

self.DirectAction = DirectAction

self._mode = 'inAuto'

self._log = []

self._errorP0 = 0

self._errorD0 = 0

self._errorD1 = 0

self._lastT = 0

self._currT = 0

def auto(self):

"""Change to automatic control mode. In automatic control mode the .update()

method computes new values for the manipulated variable using a velocity algorithm.

"""

self._mode = 'inAuto'

def manual(self):

"""Change to manual control mode. In manual mode the setpoint tracks the process

variable to provide bumpless transfer on return to automatic model.

"""

self._mode = 'inManual'

def _logger(self,t,SP,PV,MV):

"""The PID simulator logs values of time (t), setpoint (SP), process variable (PV),

and manipulated variable (MV) that can be plotted with the .plot() method.

"""

self._log.append([t,SP,PV,MV])

def plot(self):

"""Create historical plot of SP,PV, and MV using the controller's internal log file.

"""

dlog = np.asarray(self._log).T

t,SP,PV,MV = dlog

plt.subplot(2,1,1)

plt.plot(t,PV,t,SP)

plt.title('Process Variable')

plt.xlabel('Time')

plt.legend(['PV','SP'])

plt.subplot(2,1,2)

plt.plot(t,MV)

plt.title('Manipulated Variable')

plt.xlabel('Time')

plt.tight_layout()

@property

def beta(self):

"""beta is the setpoint weighting for proportional control where the proportional error

is given by error_proportional = beta*SP - PV. The default value is one.

"""

return self._beta

@beta.setter

def beta(self,beta):

self._beta = max(0.0,min(1.0,beta))

@property

def DirectAction(self):

"""DirectAction is a logical variable setting the direction of the control. A True

value means the controller output MV should increase for PV > SP. If False the controller

is reverse acting, and ouput MV will increase for SP > PV. IFf the steady state

process gain is positive then a control will be reverse acting.

The default value is False.

"""

return self._DirectAction

@DirectAction.setter

def DirectAction(self,DirectAction):

if DirectAction:

self._DirectAction = True

self._action = +1.0

else:

self._DirectAction = False

self._action = -1.0

@property

def gamma(self):

"""gamma is the setpoint weighting for derivative control where the derivative error

is given by gamma*SP - PV. The default value is zero.

"""

return self._gamma

@gamma.setter

def gamma(self,gamma):

self._gamma = max(0.0,min(1.0,gamma))

@property

def Kp(self):

"""Kp is the proportional control gain.

"""

return self._Kp

@Kp.setter

def Kp(self,Kp):

self._Kp = Kp

@property

def Ki(self):

"""Ki is the integral control gain.

"""

return self._Ki

@Ki.setter

def Ki(self,Ki):

self._Ki = Ki

@property

def Kd(self):

"""Kd is the derivative control gain.

"""

return self._Kd

@Kd.setter

def Kd(self,Kd):

self._Kd = Kd

@property

def MV(self):

"""MV is the manipulated (or PID outpout) variable. It is automatically

restricted to the limits given in MVrange.

"""

return self._MV

@MV.setter

def MV(self,MV):

self._MV = max(self._MVmin,min(self._MVmax,MV))

@property

def MVrange(self):

"""range is a tuple specifying the minimum and maximum controller output.

Default value is (0,100).

"""

return (self._MVmin,self._MVmax)

@MVrange.setter

def MVrange(self,MVrange):

self._MVmin = MVrange[0]

self._MVmax = MVrange[1]

@property

def SP(self):

"""SP is the setpoint for the measured process variable.

"""

return self._SP

@SP.setter

def SP(self,SP):

self._SP = SP

@property

def PV(self):

"""PV is the measured process (or control) variable.

"""

return self._PV

@PV.setter

def PV(self,PV):

self._PV = PV

def update(self,t,SP,PV,MV):

self.SP = SP

self.PV = PV

self.MV = MV

if t > self._lastT:

dt = t - self._lastT

self._lastT = t

if self._mode=='inManual':

self.SP = PV

self._errorP1 = self._errorP0

self._errorP0 = self.beta*self.SP - self.PV

self._errorI0 = self.SP - self.PV

self._errorD2 = self._errorD1

self._errorD1 = self._errorD0

self._errorD0 = self.gamma*self.SP - self.PV

if self._mode=='inAuto':

self._deltaMV = self.Kp*(self._errorP0 - self._errorP1) \

+ self.Ki*dt*self._errorI0 \

+ self.Kd*(self._errorD0 - 2*self._errorD1 + self._errorD2)/dt

self.MV -= self._action*self._deltaMV

self._logger(t,self.SP,self.PV,self.MV)

return self.MV