Pyomo Model of the Double Pipe Heat Exchanger

Contents

1.6. Pyomo Model of the Double Pipe Heat Exchanger¶

This is additional material regarding the modeling and analysis of the double pipe heat exchanger. If you are using this notebook in Google Colab, run the following cell to import needed libraries to run the notebook code.

import sys

if "google.colab" in sys.modules:

!pip install -q pyomo

!wget -N -q "https://ampl.com/dl/open/ipopt/ipopt-linux64.zip"

!unzip -o -q ipopt-linux64

1.6.1. Temperature Dependence Heat Transfer Coefficient¶

1.6.1.1. Dittus-Boelter Equation¶

The Prandtl number for water is a reasonably strong function of temperature over the operating range of this heat exchanger.

where

1.6.1.2. Whitaker Correlation¶

From a meta-analysis of data for well developed turbulent flow in a pipe, Stephen Whitaker proposed a correlation

where \(b\) refers to the bulk liquid and \(0\) to liquid at the wall surface. The reference temperature for computing material propoerties is bulk liquid.

where \(h\) is the local heat transfer coefficient corresponding to \(U\) in these notes. \(D\) denotes hydraulic diameter, and \(A_p\) is the cross-sectional area (\(A_p = \frac{\pi D_H^2}{4}\)).

For water in the temperature range of interest, both \(\rho\) and \(c_p\) are weak functions of temperature. Therefore we write a correlation for \(U\) as

where \(C\) is treated as a constant

1.6.2. Colburn’s Analogy¶

Colburn’s analogy between momentum and heat transfer in turbulent flow yields a correlation

where properties are evaluated at the bulk flow temperature.

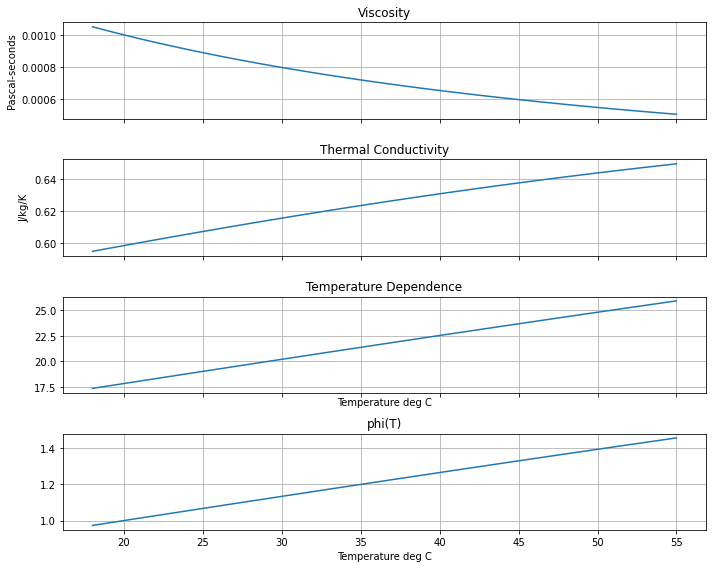

1.6.2.1. Physical property equations from¶

Pátek, J., Hrubý, J., Klomfar, J., Součková, M., & Harvey, A. H. (2009). Reference correlations for thermophysical properties of liquid water at 0.1 MPa. Journal of Physical and Chemical Reference Data, 38(1), 21-29. https://aip.scitation.org/doi/10.1063/1.3043575

import numpy as np

import math

import matplotlib.pyplot as plt

cp = 4183.0 # J/kg/K

def viscosity(T):

ac = [280.68, 511.45, 61.131, 0.45903]

bc = [-1.9, -7.7, -19.6, -40.0]

Tr = (T + 273.15)/300

return 1e-6*sum(a*Tr**b for a, b in zip(ac, bc))

def thermal_conductivity(T):

Tr = (T + 273.15)/300

cc = [0.80201, -0.25992, 0.10024, -0.032005]

dc = [-0.32, -5.7, -12.0, -15.0]

return sum(c*Tr**d for c, d in zip(cc, dc))

def temperature_dependence(T_centigrade):

return thermal_conductivity(T_centigrade)**(2/3) * viscosity(T_centigrade)**(-7/15)

def phi(T_centigrade):

return temperature_dependence(T_centigrade)/temperature_dependence(20)

T = np.linspace(18, 55)

fig, ax = plt.subplots(4, 1, figsize=(10, 8), sharex=True)

ax[0].plot(T, list(map(viscosity, T)))

ax[0].set_title("Viscosity")

ax[0].set_ylabel("Pascal-seconds")

ax[0].grid(True)

ax[1].plot(T, list(map(thermal_conductivity, T)))

ax[1].set_title("Thermal Conductivity")

ax[1].set_ylabel("J/kg/K")

ax[1].grid(True)

ax[2].plot(T, list(map(temperature_dependence, T)))

ax[2].set_title("Temperature Dependence")

ax[2].set_xlabel("Temperature deg C")

ax[2].grid(True)

ax[3].plot(T, list(map(phi, T)))

ax[3].set_title("phi(T)")

ax[3].set_xlabel("Temperature deg C")

ax[3].grid(True)

plt.tight_layout()

1.6.3. Pyomo DAE Model for Double Pipe Heat Exchanger¶

Let \(y\) be a binary indicator variable

A model for the double-pipe heat exchanger is given by

where \(T_w\) is the intermediate wall temperature, and where \(U_h\) and \(U_c\) are temperature dependent heat transfer coefficients. Temperature dependent physical properties are determined at the temperatures of the bulk fluids. Experiments have demonstrated the heat transfer resistance of the tube wall is negligible compared to the heat transfer resistances in the bulk flow. The variable \(y\) forms a one-parameter homotopy extending from counter-current flow (\(y=0\)) to co-current flow (\(y=1\)).

From the Colburn analogy, we assume

where \(F(T)\) is the temperature dependent function of thermal conductivity and viscosity, and

Two parameters, \(C_h'\) and \(C_c'\) are needed to because of the different pipe geometries for the hot and cold streams.

Parameter \(C_h = C_h'F(T_0)\) and \(C_c = C_c'F(T_0)\) will be determined by parameter estimation from experimental data. The normalization function

is used to normalize \(C_h'\) and \(C_c'\). The normalized parameters \(C_h\) and \(C_c\) would be the heat transfer coefficients at a reference flow of 1 liter/sec and a reference temperature \(T_0 = 20\) deg C.

import pyomo.environ as pyo

import pyomo.dae as dae

import pandas as pd

import matplotlib.pyplot as plt

def build_hx(y_flow_config=0, qh=600, qc=600, Th_feed=55.0, Tc_feed=18.0):

"""

Parameters:

y_flow_config: 0 for counter-current, 1 for co-current

qh (float): hot water flowrate in liters/hour

qc (float): cold water flowrate in liters/hour

Th_feed (float): hot water feed temperature in C

Tc_feed (float): cold water feed temperature in C

Returns a Pyomo model:

m.z: set of positions, 0 to 1.

m.Th[z]: hot water temperature profile

m.Tc[z]: cold water temperature profile

"""

assert (y_flow_config >= 0) and (y_flow_config <= 1), "Unrealizalbe flow configuration"

# known parameter values

A = 0.5 # square meters

Cp = 4184 # Joules/kg/deg C

rho = 1.0 # 1 kg/liter

m = pyo.ConcreteModel()

# estimated model parameters

m.Ch = pyo.Param(mutable=True, default=5000.0)

m.Cc = pyo.Param(mutable=True, default=5000.0)

# operating inputs

m.y = pyo.Param(mutable=True, initialize=y_flow_config)

m.qh = pyo.Param(mutable=True, initialize=qh)

m.qc = pyo.Param(mutable=True, initialize=qc)

m.z = dae.ContinuousSet(bounds=(0, 1))

m.Th = pyo.Var(m.z, initialize=Th_feed)

m.Tc = pyo.Var(m.z, initialize=Tc_feed)

m.Tw = pyo.Var(m.z, initialize=(Th_feed + Tc_feed)/2)

m.Uh = pyo.Var(m.z, initialize=1500)

m.Uc = pyo.Var(m.z, initialize=1500)

m.dTh = dae.DerivativeVar(m.Th, wrt=m.z)

m.dTc = dae.DerivativeVar(m.Tc, wrt=m.z)

# feed conditions

m.Tc[0].fix(Tc_feed)

@m.Constraint()

def flow_configuration(m):

return m.y*m.Th[0] + (1 - m.y)*m.Th[1] == Th_feed

# local heat transfer coefficients

@m.Constraint(m.z)

def heat_transfer_ho(m, z):

return m.Uh[z] == m.Ch * (m.qh/3600)**0.8 * phi(m.Th[z])

@m.Constraint(m.z)

def heat_transfer_cold(m, z):

return m.Uc[z] == m.Cc * (m.qc/3600)**0.8 * phi(m.Tc[z])

# stream energy balances

@m.Constraint(m.z)

def dThdz(m, z):

return rho*Cp*(m.qh/3600)*m.dTh[z] == (1 - 2*m.y) * m.Uh[z]*A*(m.Th[z] - m.Tw[z])

@m.Constraint(m.z)

def dTcdz(m, z):

return rho*Cp*(m.qc/3600)*m.dTc[z] == m.Uc[z]*A*(m.Th[z] - m.Tw[z])

# wall energy balance

@m.Constraint(m.z)

def wall(m, z):

return m.Uh[z]*(m.Th[z] - m.Tw[z]) == m.Uc[z]*(m.Tw[z] - m.Tc[z])

pyo.TransformationFactory('dae.finite_difference').apply_to(m, nfe=20, wrt=m.z)

# function to solve the model

m.solve = lambda: pyo.SolverFactory("ipopt").solve(m)

# function to plot the results

def _visualize(ax):

df = pd.DataFrame({

"Th": [m.Th[z]() for z in m.z],

"Tw": [m.Tw[z]() for z in m.z],

"Tc": [m.Tc[z]() for z in m.z],

"Uh": [m.Uh[z]() for z in m.z],

"Uc": [m.Uc[z]() for z in m.z],

}, index=m.z)

if ax is None:

fig, ax = plt.subplots(1, 1)

df.plot(y=["Th", "Tc", "Tw"], ax=ax, grid=True, lw=3)

df.plot(y=["Uh", "Uc"], ax=ax, secondary_y=True, grid=True, lw=3, style=['--', '--'])

ax.set_xlabel("Position")

ax.set_ylabel("deg C")

ax.set_title(f"Qc = {qc}, Qh = {qh}")

plt.tight_layout()

return ax

m.visualize = lambda ax=None: _visualize(ax)

return m

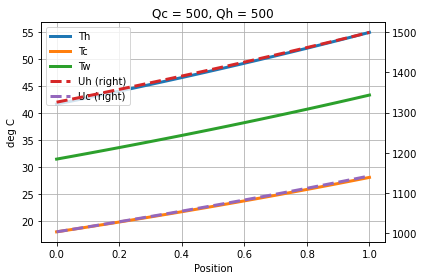

hx_model = build_hx(y_flow_config=0, qc=500, qh=500)

hx_model.solve()

hx_model.visualize()

<AxesSubplot:title={'center':'Qc = 500, Qh = 500'}, xlabel='Position', ylabel='deg C'>

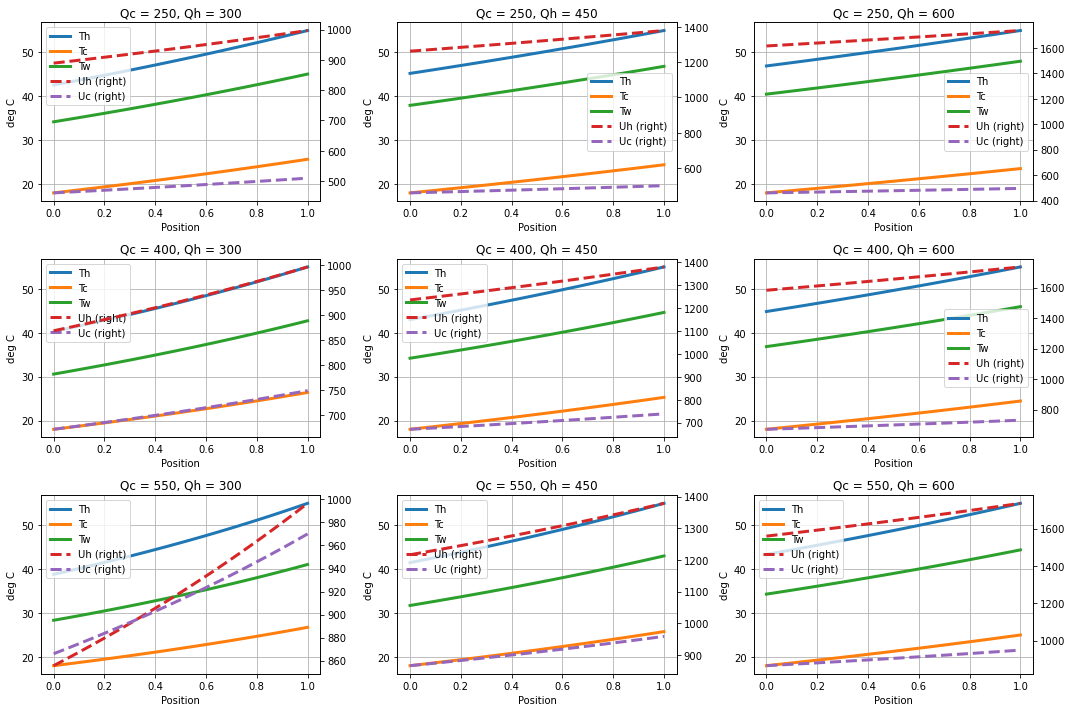

1.6.4. Comparing simulations to experimental data¶

# guess parameter values for heat transfer model

Cc = 4000

Ch = 5000

# set grid of flowrates

Qh = [300, 450, 600]

Qc = [250, 400, 550]

# set grid of plots

fig, ax = plt.subplots(len(Qc), len(Qh), figsize=(15, 10))

# do simulations

for i, qc in enumerate(Qc):

for j, qh in enumerate(Qh):

hx_model = build_hx(y_flow_config=0, qc=qc, qh=qh)

hx_model.Cc = Cc

hx_model.Ch = Ch

hx_model.solve()

hx_model.visualize(ax[i, j])

# overlay temperature measurements

for i, qc in enumerate(Qc):

for j, qh in enumerate(Qh):

z_pos = []

Th_data = []

Tc_data = []

ax[i, j].plot(z_pos, Th_data, 'r.', z_pos, Tc_data, 'b.', ms=10)

1.6.5. Parameter Estimation¶

The model is parameterized by two coefficients \(C_h\) and \(C_c\) in the heat transfer model. The goal for parameter estimation is to find a values for \(C_h\) and \(C_c\) that fit the model over full operating range:

Operationally, the model wilk be used to determine the hot water flow necessary to temper the cold stream to a desired temperature at a desired flowrate. That is, given feed temperatures, flow configuration, desired cold stream flow and cold exit temperature, the model will be used to compute the required hot stream flowrate. The quality of the model will be measured by comparing the model’s prediction for cold exit temperature to actual measurements.

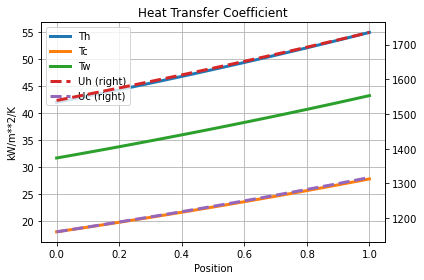

hx_model = build_hx()

hx_model.y = 0

hx_model.solve()

hx_model.visualize()

<AxesSubplot:title={'center':'Heat Transfer Coefficient'}, xlabel='Position', ylabel='kW/m**2/K'>