Job Shop Scheduling

Contents

Job Shop Scheduling#

Background#

A job shop consists of a set of distinct machines that process jobs. Each job is a series of tasks that require use of particular machines for known durations, and which must be completed in specified order. The job shop scheduling problem is to schedule the jobs on the machines to minimize the time necessary to process all jobs (i.e, the makespan) or some other metric of productivity. Job shop scheduling is one of the classic problems in Operations Research.

Data consists of two tables. The first table is decomposition of the jobs into a series of tasks. Each task lists a job name, name of the required machine, and task duration. The second table list task pairs where the first task must be completed before the second task can be started. This formulation is quite general, but can also specify situations with no feasible solutions.

Job Shop Example#

The following example of a job shop is from from Christelle Gueret, Christian Prins, Marc Sevaux, “Applications of Optimization with Xpress-MP,” Dash Optimization, 2000.

In this example, there are three printed paper products that must pass through color printing presses in a particular order. The given data consists of a flowsheet showing the order in which each job passes through the color presses

and a table of data showing, in minutes, the amount of time each job requires on each machine.

Machine |

Color |

Paper 1 |

Paper 2 |

Paper 3 |

|---|---|---|---|---|

1 |

Blue |

45 |

20 |

12 |

2 |

Green |

- |

10 |

17 |

3 |

Yellow |

10 |

34 |

28 |

What is the minimum amount of time (i.e, what is the makespan) for this set of jobs?

Task Decomposition#

The first step in the analysis is to decompose the process into a series of tasks. Each task is a (job,machine) pair. Some tasks cannot start until a prerequisite task is completed.

Task (Job,Machine) |

Duration |

Prerequisite Task |

|---|---|---|

(Paper 1, Blue) |

45 |

- |

(Paper 1, Yellow) |

10 |

(Paper 1,Blue) |

(Paper 2, Blue) |

20 |

(Paper 2, Green) |

(Paper 2, Green) |

10 |

- |

(Paper 2, Yellow) |

34 |

(Paper 2, Blue) |

(Paper 3, Blue) |

12 |

(Paper 3, Yellow) |

(Paper 3, Green) |

17 |

(Paper 3, Blue) |

(Paper 3, Yellow) |

28 |

- |

We convert this to a JSON style representation where tasks are denoted by (Job,Machine) tuples in Python. The task data is stored in a Python dictionary indexed by (Job,Machine) tuples. The task data conists of a dictionary with duration (‘dur’) and (Job,Machine) pair for any prerequisite task.

TASKS = {

('Paper_1','Blue') : {'dur': 45},

('Paper_1','Yellow') : {'dur': 10, 'prec': ('Paper_1','Blue')},

('Paper_2','Blue') : {'dur': 20, 'prec': ('Paper_2','Green')},

('Paper_2','Green') : {'dur': 10},

('Paper_2','Yellow') : {'dur': 34, 'prec': ('Paper_2','Blue')},

('Paper_3','Blue') : {'dur': 12, 'prec': ('Paper_3','Yellow')},

('Paper_3','Green') : {'dur': 17, 'prec': ('Paper_3','Blue')},

('Paper_3','Yellow') : {'dur': 28},

}

Model Formulation#

Each task is represented as an ordered pair \((j,m)\) where \(j\) is a job, and \(m\) is a machine.

Parameter |

Description |

|---|---|

\(\text{dur}_{j,m}\) |

Duration of task \((j,m)\) |

\(\text{prec}_{j,m}\) |

A task \((k,n) = \text{Prec}_{j,m}\) that must be completed before task \((j,m)\) |

Decision Variables |

Description |

|---|---|

\(\text{makespan}\) |

Completion of all jobs |

\(\text{start}_{j,m}\) |

Start time for task \((j,m)\) |

\(y_{j,k,m}\) |

boolean variable for tasks \((i,m)\) and \((j,m)\) on machine \(m\) where \(j < k\) |

Upper and lower bounds on the start and completion of task \((j,m)\)

\begin{align} \text{start}{j,m} & \geq 0\ \text{start}{j,m}+\text{Dur}_{j,m} & \leq \text{makespan} \end{align}

Satisfying prerequisite tasks

\begin{align} \text{start}{k,n}+\text{Dur}{k,n}\leq\text{start}{j,m}\ \ \ \ \text{for } (k,n) =\text{Prec}{j,m} \end{align}

Disjunctive Constraints

If \(M\) is big enough, then satisfying \begin{align} \text{start}{j,m}+\text{Dur}{j,m} & \leq \text{start}{k,m}+M(1 - y{j,k,m})\ \text{start}{k,m}+\text{Dur}{k,m} & \leq \text{start}{j,m}+My{j,k,m} \end{align}

avoids conflicts for use of the same machine.

Pyomo Implementation#

The job shop scheduling problem is implemented below in Pyomo. The implementation consists of of a function JobShop(TASKS) that accepts a dictionary of tanks and returns a pandas dataframe containing an optimal schedule of tasks. An optional argument to JobShop allows one to specify a solver.

from pyomo.environ import *

import pandas as pd

def JobShop(TASKS, solver='glpk'):

model = ConcreteModel()

JOBS = set()

MACHINES = set()

for (j, m) in TASKS.keys():

JOBS.add(j)

MACHINES.add(m)

BigM = 1 + sum([TASKS[(j,m)]['dur'] for (j,m) in TASKS.keys()])

model.start = Var(JOBS, MACHINES, domain=NonNegativeReals)

model.makespan = Var(domain=NonNegativeReals)

model.y = Var(JOBS,JOBS,MACHINES, domain=Boolean)

@model.Objective(sense=minimize)

def Obj(m):

return model.makespan

model.cons = ConstraintList()

for (j,m) in TASKS.keys():

model.cons.add(model.start[j,m] + TASKS[(j,m)]['dur'] <= model.makespan)

if 'prec' in TASKS[(j,m)]:

(k,n) = TASKS[(j,m)]['prec']

model.cons.add(model.start[j,m] >= model.start[k,n] + TASKS[(k,n)]['dur'])

for m in MACHINES:

for j in JOBS:

for k in JOBS:

if (j < k) and (j,m) in TASKS.keys() and (k,m) in TASKS.keys():

model.cons.add(model.start[j,m] + TASKS[(j,m)]['dur']

<= model.start[k,m] + BigM*(1-model.y[j,k,m]))

model.cons.add(model.start[k,m] + TASKS[(k,m)]['dur']

<= model.start[j,m] + BigM*(model.y[j,k,m]))

# solve with indicated solver

SolverFactory(solver).solve(model)

# create pandas dataframe with the optimal schedule

results = [[j, m, model.start[j, m](), TASKS[(j, m)]['dur'], model.start[j, m]() + TASKS[(j, m)]['dur']]

for (j, m) in TASKS]

schedule = pd.DataFrame(results, columns=['Job', 'Machine', 'Start', 'Duration', 'Finish'])

schedule = schedule.sort_values(by='Start')

schedule.set_index(['Job', "Machine"], inplace=True)

return schedule

schedule = JobShop(TASKS)

Displaying a Solution#

def Textualize(schedule):

JOBS = list(schedule.index.get_level_values('Job').unique())

MACHINES = list(schedule.index.get_level_values('Machine').unique())

print('\nJOB SCHEDULES\n')

for j in sorted(JOBS):

print("Job: " + j)

print(schedule.xs(j,level=0))

print('')

print('\nMACHINE SCHEDULES\n')

for m in MACHINES:

print("Machine: " + m)

print(schedule.xs(m,level=1))

print('')

Textualize(schedule)

JOB SCHEDULES

Job: Paper_1

Start Duration Finish

Machine

Blue 42.0 45 87.0

Yellow 87.0 10 97.0

Job: Paper_2

Start Duration Finish

Machine

Green 0.0 10 10.0

Blue 10.0 20 30.0

Yellow 53.0 34 87.0

Job: Paper_3

Start Duration Finish

Machine

Yellow 0.0 28 28.0

Blue 30.0 12 42.0

Green 42.0 17 59.0

MACHINE SCHEDULES

Machine: Green

Start Duration Finish

Job

Paper_2 0.0 10 10.0

Paper_3 42.0 17 59.0

Machine: Yellow

Start Duration Finish

Job

Paper_3 0.0 28 28.0

Paper_2 53.0 34 87.0

Paper_1 87.0 10 97.0

Machine: Blue

Start Duration Finish

Job

Paper_2 10.0 20 30.0

Paper_3 30.0 12 42.0

Paper_1 42.0 45 87.0

Visualizing Results with Gantt Charts#

import matplotlib.pyplot as plt

import matplotlib as mpl

%matplotlib inline

def Visualize(schedule):

JOBS = list(schedule.index.get_level_values('Job').unique())

MACHINES = list(schedule.index.get_level_values('Machine').unique())

makespan = schedule['Finish'].max()

plt.figure(figsize=(12, 5 + (len(JOBS)+len(MACHINES))/4))

plt.subplot(2,1,1)

jdx = 0

for j in sorted(JOBS):

jdx += 1

mdx = 0

for m in MACHINES:

mdx += 1

c = mpl.cm.Dark2.colors[mdx%7]

if (j,m) in schedule.index:

plt.plot([schedule.loc[(j,m),'Start'],schedule.loc[(j,m),'Finish']],

[jdx,jdx],color = c,alpha=1.0,lw=25,solid_capstyle='butt')

plt.text((schedule.loc[(j,m),'Start'] + schedule.loc[(j,m),'Finish'])/2.0,jdx,

m, color='white', weight='bold',

horizontalalignment='center', verticalalignment='center')

plt.ylim(0.5,jdx+0.5)

plt.title('Job Schedule')

plt.gca().set_yticks(range(1,1+len(JOBS)))

plt.gca().set_yticklabels(sorted(JOBS))

plt.plot([makespan,makespan],plt.ylim(),'r--')

plt.text(makespan,plt.ylim()[0]-0.2,str(round(makespan,2)),

horizontalalignment='center', verticalalignment='top')

plt.xlabel('Time')

plt.grid()

plt.subplot(2,1,2)

mdx = 0

for m in sorted(MACHINES):

mdx += 1

jdx = 0

for j in JOBS:

jdx += 1

c = mpl.cm.Dark2.colors[jdx%7]

if (j,m) in schedule.index:

plt.plot([schedule.loc[(j,m),'Start'],schedule.loc[(j,m),'Finish']],

[mdx,mdx],color = c,alpha=1.0,lw=25,solid_capstyle='butt')

plt.text((schedule.loc[(j,m),'Start'] + schedule.loc[(j,m),'Finish'])/2.0,mdx,

j, color='white', weight='bold',

horizontalalignment='center', verticalalignment='center')

plt.ylim(0.5,mdx+0.5)

plt.title('Machine Schedule')

plt.gca().set_yticks(range(1,1+len(MACHINES)))

plt.gca().set_yticklabels(sorted(MACHINES))

plt.plot([makespan,makespan],plt.ylim(),'r--')

plt.text(makespan,plt.ylim()[0]-0.2,str(round(makespan,2)),

horizontalalignment='center', verticalalignment='top')

plt.xlabel('Time')

plt.grid()

plt.tight_layout()

Visualize(schedule)

Application to Scheduling of Batch Processes#

We will now turn our attention to the application of the job shop scheduling problem to the short term scheduling of batch processes. We illustrate these techniques using an example from Dunn (2013).

Process |

Mixer |

Reactor |

Separator |

Packaging |

|---|---|---|---|---|

A |

1.0 |

5.0 |

4.0 |

1.5 |

B |

- |

- |

4.5 |

1.0 |

C |

- |

3.0 |

5.0 |

1.5 |

Single Product Strategies#

Before going further, we create a function to streamline the generation of T

def Recipe(jobs, machines, durations):

TASKS = {}

for j in jobs:

prec = (None, None)

for m, d in zip(machines, durations):

task = (j, m)

if prec == (None, None):

TASKS.update({(j, m): {'dur': d}})

else:

TASKS.update({(j, m): {'dur': d, 'prec': prec}})

prec = task

return TASKS

RecipeA = Recipe('A', ['Mixer', 'Reactor', 'Separator',' Packaging'], [1, 5, 4, 1.5])

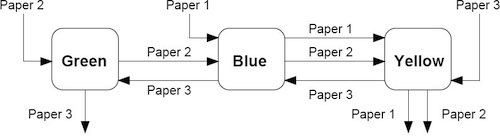

RecipeB = Recipe('B', ['Separator', 'Packaging'], [4.5, 1])

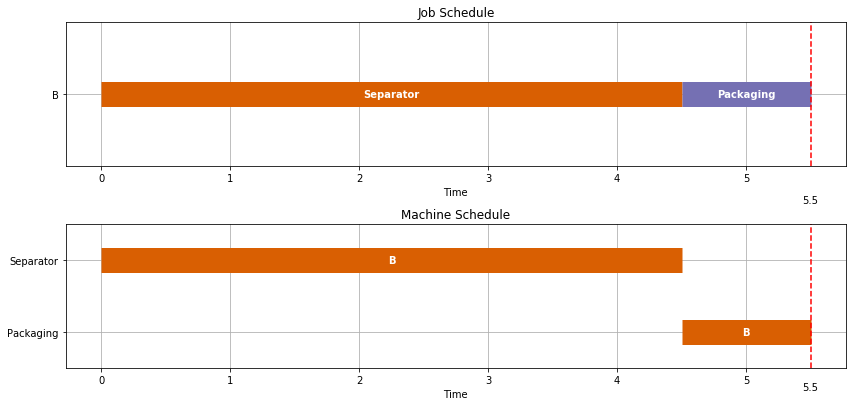

RecipeC = Recipe('C', ['Separator', 'Reactor', 'Packaging'], [5, 3, 1.5])

Visualize(JobShop(RecipeA))

Visualize(JobShop(RecipeB))

Visualize(JobShop(RecipeC))

Overlapping Tasks#

Let’s now consider an optimal scheduling problem where we are wish to make two batches of Product A.

TASKS = Recipe(['A1','A2'],['Mixer','Reactor','Separator','Packaging'],[1,5,4,1.5])

schedule = JobShop(TASKS, solver='gurobi')

Visualize(schedule)

print(schedule['Finish'].max())

16.5

Earlier we found it tood 11.5 hours to produce one batch of product A. As we see here, we can produce a second batch with only 5.0 additional hours because some of the tasks overlap. The overlapping of tasks is the key to gaining efficiency in batch processing facilities.

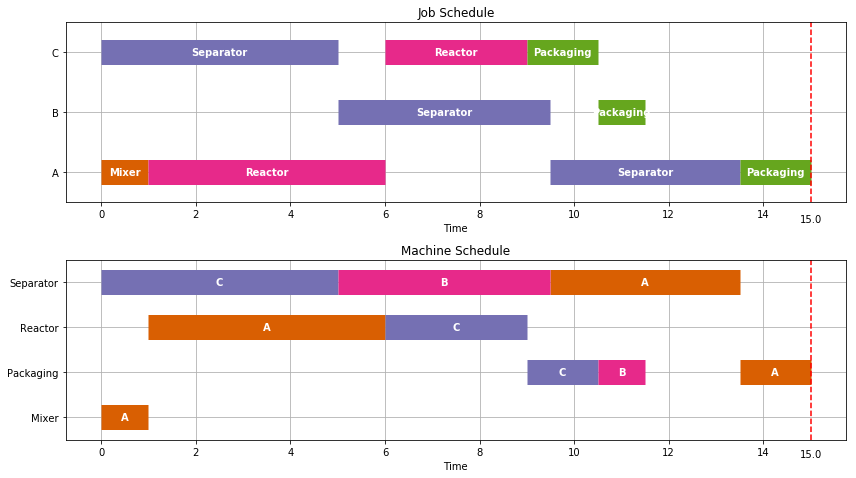

Let’s next consider production of a single batch each of products A, B, and C.

TASKS = RecipeA

TASKS.update(RecipeB)

TASKS.update(RecipeC)

schedule = JobShop(TASKS, solver='cbc')

Visualize(schedule)

print(schedule['Finish'].max())

15.0

The individual production of A, B, and C required 11.5, 5.5, and 9.5 hours, respectively, for a total of 25.5 hours. As we see here, by scheduling the production simultaneously, we can get all three batches done in just 15 hours.

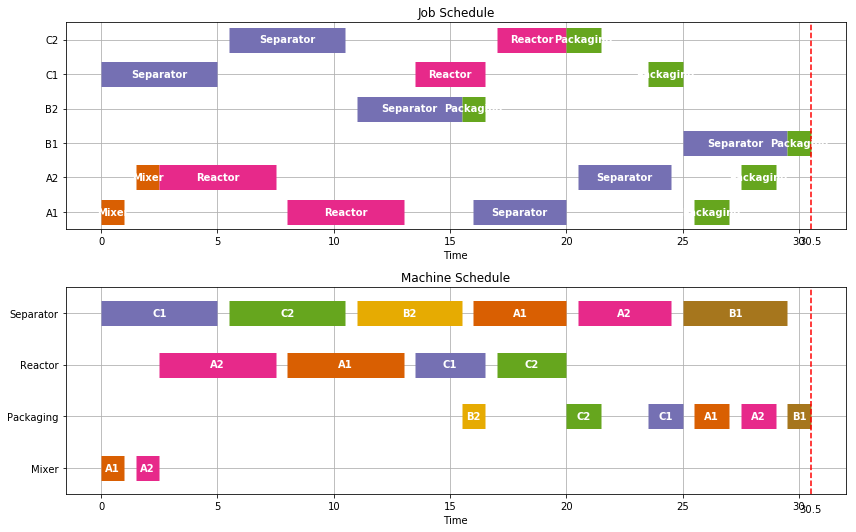

As we see below, each additional set of three products takes an additionl 13 hours. So there is considerable efficiency gained by scheduling over longer intervals whenever possible.

TASKS = Recipe(['A1','A2'],['Mixer','Reactor','Separator','Packaging'],[1,5,4,1.5])

TASKS.update(Recipe(['B1','B2'],['Separator','Packaging'],[4.5,1]))

TASKS.update(Recipe(['C1','C2'],['Separator','Reactor','Packaging'],[5,3,1.5]))

schedule = JobShop(TASKS,solver='gurobi')

Visualize(schedule)

print(schedule['Finish'].max())

27.9999990802

Unit Cleanout#

A common feature in batch unit operations is a requirement that equipment be cleaned prior to reuse.

In most cases the time needed for clean out would be equipment and product specific. Bur for the purposes of illustration, we implement this policy with a single non-negative parameter \(t_{clean} \geq 0\) which, if specified, requires a period no less than \(t_{clean}\) between the finish of one task and the start of another on every piece of equipment.

This is implemented by modifying the usual disjunctive constraints to avoid machine conflicts, i.e.,

\begin{align} \text{start}{j,m}+\text{Dur}{j,m} & \leq \text{start}{k,m}+M(1 - y{j,k,m})\ \text{start}{k,m}+\text{Dur}{k,m} & \leq \text{start}{j,m}+My{j,k,m} \end{align}

to read

\begin{align} \text{start}{j,m}+\text{Dur}{j,m} + t_{clean} & \leq \text{start}{k,m}+M(1 - y{j,k,m})\ \text{start}{k,m}+\text{Dur}{k,m} + t_{clean} & \leq \text{start}{j,m}+My{j,k,m} \end{align}

for sufficiently large \(M\).

from pyomo.environ import *

import pandas as pd

def JobShop(TASKS, solver='glpk', tclean = 0):

model = ConcreteModel()

JOBS = set()

MACHINES = set()

for (j,m) in TASKS.keys():

JOBS.add(j)

MACHINES.add(m)

BigM = 1 + sum([TASKS[(j,m)]['dur'] for (j,m) in TASKS.keys()])

model.start = Var(JOBS, MACHINES, domain = NonNegativeReals)

model.makespan = Var(domain=NonNegativeReals)

model.y = Var(JOBS,JOBS,MACHINES, domain = Boolean)

model.Obj = Objective(expr = model.makespan, sense = minimize)

model.cons = ConstraintList()

for (j,m) in TASKS.keys():

model.cons.add(model.start[j,m] + TASKS[(j,m)]['dur'] + tclean <= model.makespan)

if 'prec' in TASKS[(j,m)]:

(k,n) = TASKS[(j,m)]['prec']

model.cons.add(model.start[j,m] >= model.start[k,n] + TASKS[(k,n)]['dur'])

for m in MACHINES:

for j in JOBS:

for k in JOBS:

if (j < k) and (j,m) in TASKS.keys() and (k,m) in TASKS.keys():

model.cons.add(model.start[j,m] + TASKS[(j,m)]['dur'] + tclean

<= model.start[k,m] + BigM*(1-model.y[j,k,m]))

model.cons.add(model.start[k,m] + TASKS[(k,m)]['dur'] + tclean

<= model.start[j,m] + BigM*(model.y[j,k,m]))

# solve with indicated solver

SolverFactory(solver).solve(model)

# create pandas dataframe with the optimal schedule

results = [[j,m,model.start[j,m](),TASKS[(j,m)]['dur'], model.start[j,m]() + TASKS[(j,m)]['dur']]

for (j,m) in TASKS]

schedule = pd.DataFrame(results,columns=['Job','Machine','Start','Duration','Finish'])

schedule = schedule.sort_values(by='Start')

schedule.set_index(['Job',"Machine"], inplace=True)

return schedule

TASKS = Recipe(['A1','A2'],['Mixer','Reactor','Separator','Packaging'],[1,5,4,1.5])

TASKS.update(Recipe(['B1','B2'],['Separator','Packaging'],[4.5,1]))

TASKS.update(Recipe(['C1','C2'],['Separator','Reactor','Packaging'],[5,3,1.5]))

schedule = JobShop(TASKS, solver='gurobi', tclean=0.5)

Visualize(schedule)

print("Makespan = ", schedule['Finish'].max())

Makespan = 30.5

Zero Wait Policy#

One of the issues in the use of job shop scheduling for batch processing are situations where there it isn’t possible to store intermediate materials. If there is no way to store intermediates, either in the processing equipment or in external vessels, then a zero-wait policy may be appropriate.

A zero-wait policy requires subsequent processing machines to be available immediately upon completion of any task. To implement this policy, the usual precident sequencing constraint of a job shop scheduling problem, i.e.,

\begin{align*} \text{start}{k,n}+\text{Dur}{k,n} \leq \text{start}{j,m}\ \ \ \ \text{for } (k,n) =\text{Prec}{j,m} \end{align*}

is changed to

\begin{align*} \text{start}{k,n}+\text{Dur}{k,n} = \text{start}{j,m}\ \ \ \ \text{for } (k,n) =\text{Prec}{j,m}\text{ and ZW is True} \end{align*}

if the zero-wait policy is in effect.

While this could be implemented on an equipment or product specific basis, here we add an optional ZW flag to the JobShop function that, by default, is set to False.

from pyomo.environ import *

import pandas as pd

def JobShop(TASKS, solver='glpk', tclean = 0, ZW = False):

model = ConcreteModel()

JOBS = set()

MACHINES = set()

for (j,m) in TASKS.keys():

JOBS.add(j)

MACHINES.add(m)

BigM = 1 + sum([TASKS[(j,m)]['dur'] for (j,m) in TASKS.keys()])

model.start = Var(JOBS, MACHINES, domain = NonNegativeReals)

model.makespan = Var(domain=NonNegativeReals)

model.y = Var(JOBS,JOBS,MACHINES, domain = Boolean)

model.Obj = Objective(expr = model.makespan, sense = minimize)

model.cons = ConstraintList()

for (j,m) in TASKS.keys():

model.cons.add(model.start[j,m] + TASKS[(j,m)]['dur'] + tclean <= model.makespan)

if 'prec' in TASKS[(j,m)]:

(k,n) = TASKS[(j,m)]['prec']

if ZW:

model.cons.add(model.start[j,m] == model.start[k,n] + TASKS[(k,n)]['dur'])

else:

model.cons.add(model.start[j,m] >= model.start[k,n] + TASKS[(k,n)]['dur'])

for m in MACHINES:

for j in JOBS:

for k in JOBS:

if (j < k) and (j,m) in TASKS.keys() and (k,m) in TASKS.keys():

model.cons.add(model.start[j,m] + TASKS[(j,m)]['dur'] + tclean

<= model.start[k,m] + BigM*(1-model.y[j,k,m]))

model.cons.add(model.start[k,m] + TASKS[(k,m)]['dur'] + tclean

<= model.start[j,m] + BigM*(model.y[j,k,m]))

# solve with indicated solver

SolverFactory(solver).solve(model)

# create pandas dataframe with the optimal schedule

results = [[j,m,model.start[j,m](),TASKS[(j,m)]['dur'], model.start[j,m]() + TASKS[(j,m)]['dur']]

for (j,m) in TASKS]

schedule = pd.DataFrame(results,columns=['Job','Machine','Start','Duration','Finish'])

schedule = schedule.sort_values(by='Start')

schedule.set_index(['Job',"Machine"], inplace=True)

return schedule

TASKS = Recipe(['A1','A2'],['Mixer','Reactor','Separator','Packaging'],[1,5,4,1.5])

TASKS.update(Recipe(['B1','B2'],['Separator','Packaging'],[4.5,1]))

TASKS.update(Recipe(['C1','C2'],['Separator','Reactor','Packaging'],[5,3,1.5]))

schedule = JobShop(TASKS, solver='gurobi', tclean=0.5, ZW=True)

Visualize(schedule)

print("Makespan = ", schedule['Finish'].max())

Makespan = 32.0

Benchmark Problem LA19#

Lawrence 1984, Solved in 1991. This cell can be very long running … minutes to hours. Delete the comment tag on the last line only if you wish to run the cell to see the outcome of a long and challenging calculation that represented the state-of-the-art several decades ago.

data = """

2 44 3 5 5 58 4 97 0 9 7 84 8 77 9 96 1 58 6 89

4 15 7 31 1 87 8 57 0 77 3 85 2 81 5 39 9 73 6 21

9 82 6 22 4 10 3 70 1 49 0 40 8 34 2 48 7 80 5 71

1 91 2 17 7 62 5 75 8 47 4 11 3 7 6 72 9 35 0 55

6 71 1 90 3 75 0 64 2 94 8 15 4 12 7 67 9 20 5 50

7 70 5 93 8 77 2 29 4 58 6 93 3 68 1 57 9 7 0 52

6 87 1 63 4 26 5 6 2 82 3 27 7 56 8 48 9 36 0 95

0 36 5 15 8 41 9 78 3 76 6 84 4 30 7 76 2 36 1 8

5 88 2 81 3 13 6 82 4 54 7 13 8 29 9 40 1 78 0 75

9 88 4 54 6 64 7 32 0 52 2 6 8 54 5 82 3 6 1 26

"""

TASKS = {}

prec = ''

lines = data.splitlines()

job= 0

for line in lines[1:]:

j = "J{0:1d}".format(job)

nums = line.split()

prec = ''

for m,dur in zip(nums[::2],nums[1::2]):

task = (j,'M{0:s}'.format(m))

if prec:

TASKS[task] = {'dur':int(dur), 'prec':prec}

else:

TASKS[task] = {'dur':int(dur)}

prec = task

job += 1

#Visualize(JobShop(TASKS, solver='mosek'))