2.6. Fed-Batch Bioreactor#

Batch reactors are commonly used in the production of speciality chemicals, pharmaceuticals, and beverage and food products.

Source: Sanofi Pasteur, Creative Commons License

The following links provide additional illustrations of fed-batch fermentation:

https://ib.bioninja.com.au/_Media/penicillin-production-2_med.jpeg

https://biologyreader.com/wp-content/uploads/2021/07/diagram-of-fed-batch-culture.jpg

Our goal is to demonstrate modeling of a fed-batch fermentation process. The learning goals are:

Learn to develop models for reactive systems using mass balances.

Model variable volume dilution effects.

Simulate the response of the model using Python solvers for initial value problems.

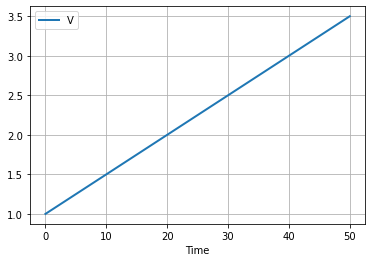

2.6.1. Modeling Tank Volume#

The volumetric inlet flowrate to a fed-batch reactor is \(F(t)\). Assuming changes in specific volume due to mixing, the volume of liquid in the reactor is given by

Assume the initial volume is 1 liter and a constant flowrate of 0.05 liters/hour. Simulate the volume of the reactor for 50 hours.

import numpy as np

import pandas as pd

from scipy.integrate import solve_ivp

# inlet flowrate

def F(t):

return 0.05

# differential equations

def deriv(t, y):

dV = F(t)

return [dV]

# initial conditions

IC = [1.0]

# integration period

t_final = 50

# solve ivp

soln = solve_ivp(deriv, [0, t_final], IC, max_step=1.0)

# extract solution into a data frame

df = pd.DataFrame(soln.y.T, columns=["V"])

df["Time"] = soln.t

# plot

df.plot(x = "Time", grid=True, lw=2)

<AxesSubplot:xlabel='Time'>

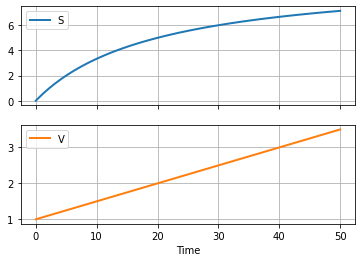

2.6.2. Modeling Substrate Composition#

The feed entering the tank carries important nutrients for the fermentation. Assume the substrate feed composition \(S_f\) is 10 grams/liter. Simulate the concentration in the fed-batch reactor.

Applying the chain rule

so the mass balance becomes

which accounts for dilution due to changing tank volume. The model now has state variables for substrate composition and tank volume.

The following cell extends our simulation model to include substrate concentration.

import numpy as np

import pandas as pd

from scipy.integrate import solve_ivp

# parameter values

Sf = 10.0 # g/liter

# inlet flowrate

def F(t):

return 0.05

# differential equations

def deriv(t, y):

S, V = y

dS = F(t)*(Sf - S)/V

dV = F(t)

return [dS, dV]

# initial conditions

IC = [0.0, 1.0]

# integration period

t_final = 50

# solve ivp

soln = solve_ivp(deriv, [0, t_final], IC, max_step=1.0)

# extract solution into a data frame

df = pd.DataFrame(soln.y.T, columns=["S", "V"])

df["Time"] = soln.t

# plot

df.plot(x = "Time", grid=True, lw=2, subplots=True)

array([<AxesSubplot:xlabel='Time'>, <AxesSubplot:xlabel='Time'>],

dtype=object)

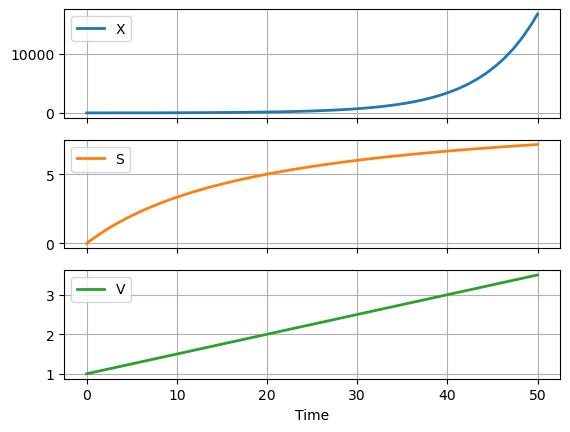

2.6.3. Modeling Biomass#

Fermentation is process in which biomass consumes substrate to produce more biomass and by-products.

The rate \(r_g(X,S)\) is the production of fresh cell biomass in units of grams/liter/hr. The volume specific growth rate is expressed as

where \(\mu(S)\) is the cell specific growth rate. In the Monod model, the cell specific growth rate is a function of substrate concentration given by

where \(\mu_{max}\) is the maximum specific growth rate, and \(K_S\) is the saturation constant. \(K_S\) is equal to the value of \(S\) for which \(\mu = \frac{1}{2}\mu_{max}\).

The overall balance for biomass is

After accounting for the dilution effect our model becomes

The following cell shows the results of incorporating biomass growth into the model for the fed-batch reaction.

import numpy as np

import pandas as pd

from scipy.integrate import solve_ivp

# parameter values

Sf = 10.0 # g/liter

mumax = 0.20 # 1/hour

Ks = 1.00 # g/liter

# inlet flowrate

def F(t):

return 0.05

# reaction rates

def mu(S):

return mumax*S/(Ks + S)

def Rg(X, S):

return mu(S)*X

# differential equations

def deriv(t, y):

X, S, V = y

dX = -F(t)*X/V + Rg(X, S)

dS = F(t)*(Sf - S)/V

dV = F(t)

return [dX, dS, dV]

# initial conditions

IC = [20.0, 0.0, 1.0]

# integration period

t_final = 50

# solve ivp

soln = solve_ivp(deriv, [0, t_final], IC, max_step=1.0)

# extract solution into a data frame

df = pd.DataFrame(soln.y.T, columns=["X", "S", "V"])

df["Time"] = soln.t

# plot

df.plot(x = "Time", grid=True, lw=2, subplots=True)

array([<AxesSubplot: xlabel='Time'>, <AxesSubplot: xlabel='Time'>,

<AxesSubplot: xlabel='Time'>], dtype=object)

Experiment with this model

At this stage the model is not complete and will give implausible simulation results. But is still important to understand what the model is doing and why the simulation results do provide the results you may expect.

Before going further with this notebook, run this notebook and experiment with different initial conditions for \(X\). Choose small values and see what happens. Why are the results different than one might expect of a fed-batch bioreactor?

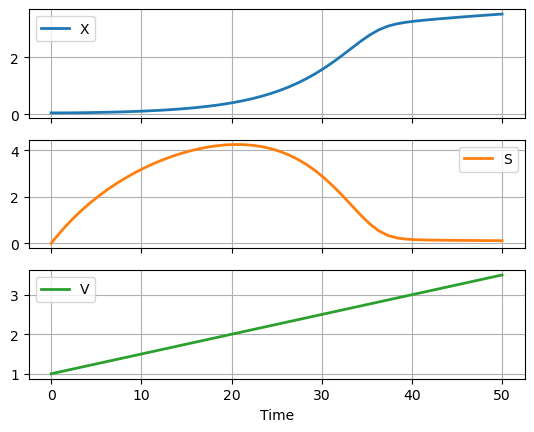

2.6.3.1. Substrate Modeling, revisited#

The growth of biomass consumes substrate which serves to limit the production of biomass. Assume the substrate is consumed is proportion to the mass of new cells formed where \(Y_{X/S}\) is the yield coefficient for new cells.

where \(\mu(S)\) is the cell specific growth rate. So the total consumption of substrate becomes

Including this in our model

import numpy as np

import pandas as pd

from scipy.integrate import solve_ivp

# parameter values

Sf = 10.0 # g/liter

mumax = 0.20 # 1/hour

Ks = 1.00 # g/liter

Yxs = 0.5 # g/g

# inlet flowrate

def F(t):

return 0.05

# reaction rates

def mu(S):

return mumax*S/(Ks + S)

def Rg(X,S):

return mu(S)*X

# differential equations

def deriv(t, y):

X, S, V = y

dX = -F(t)*X/V + Rg(X, S)

dS = F(t)*(Sf - S)/V - Rg(X,S)/Yxs

dV = F(t)

return [dX, dS, dV]

# initial conditions

IC = [0.05, 0.0, 1.0]

# integration period

t_final = 50

# solve ivp

soln = solve_ivp(deriv, [0, t_final], IC, max_step=1.0)

# extract solution into a data frame

df = pd.DataFrame(soln.y.T, columns=["X", "S", "V"])

df["Time"] = soln.t

# plot

df.plot(x = "Time", grid=True, lw=2, subplots=True)

array([<AxesSubplot: xlabel='Time'>, <AxesSubplot: xlabel='Time'>,

<AxesSubplot: xlabel='Time'>], dtype=object)

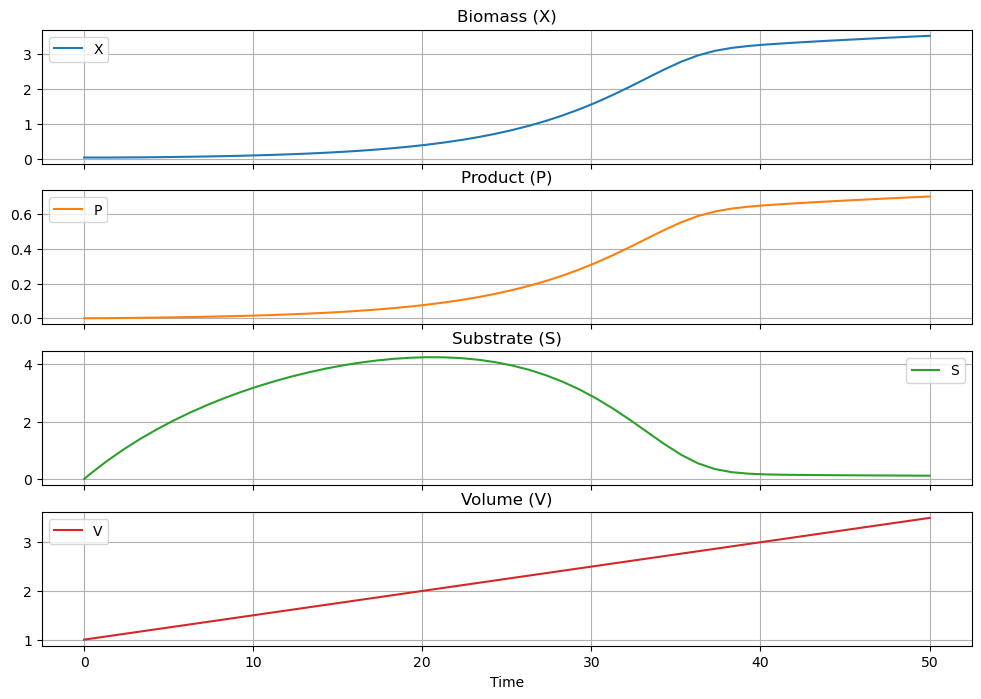

2.6.3.2. Product Modeling#

At this stage this is just one last consideration, modeling of the product produced by the fed-batch fermenter. For this model, the product is assumed to be a by-product of cell growth

where \(Y_{P/X}\) is the product yield coefficient defined as

Applying the chain rule for derivatives results in the final version of our model.

import numpy as np

import pandas as pd

from scipy.integrate import solve_ivp

# parameter values

mumax = 0.20 # 1/hour

Ks = 1.00 # g/liter

Yxs = 0.5 # g/g

Ypx = 0.2 # g/g

Sf = 10.0 # g/liter

# inlet flowrate

def F(t):

return 0.05

# reaction rates

def mu(S):

return mumax*S/(Ks + S)

def Rg(X,S):

return mu(S)*X

def Rp(X,S):

return Ypx*Rg(X,S)

# differential equations

def deriv(t, y):

X, P, S, V = y

dX = -F(t)*X/V + Rg(X,S)

dP = -F(t)*P/V + Rp(X,S)

dS = F(t)*(Sf - S)/V - Rg(X,S)/Yxs

dV = F(t)

return [dX, dP, dS, dV]

IC = [0.05, 0.0, 0, 1.0]

t_final = 50

soln = solve_ivp(deriv, [0, t_final], IC, max_step=1.0)

df = pd.DataFrame(soln.y.T, columns=["X", "P", "S", "V"])

df["Time"] = soln.t

df.plot(x = "Time", grid=True, subplots=True, figsize=(12, 8),

title=["Biomass (X)", "Product (P)", "Substrate (S)", "Volume (V)"], sharex=True)

array([<AxesSubplot: title={'center': 'Biomass (X)'}, xlabel='Time'>,

<AxesSubplot: title={'center': 'Product (P)'}, xlabel='Time'>,

<AxesSubplot: title={'center': 'Substrate (S)'}, xlabel='Time'>,

<AxesSubplot: title={'center': 'Volume (V)'}, xlabel='Time'>],

dtype=object)

2.6.4. Exercises: Putting the Simulation Model to Work#

Simulation has many uses, among them is to gain insight into operating strategies.

Exercise 1

The above simulations have been run with initial conditions \(X_0\) = 0.05 g/liter, \(V\) = 1 liter, and \(P_0\) = \(S_0\) = 0 g/liter. Suppose the economic operation of the downstream separations process require a product concentration \(P\) of at least 0.8 g/liter. How long would you have to operate the reactor? (Hint: Modify the simulation to create a terminal event corresponding to the desired product concentration. See Section 2.2 for an example, or consult the documentation for scipy.integrate.solve_ivp to see how this is done.)

Exercise 2

One problem with the operation is that the initial load of the bioreactor has no substrate. Suppose we change the operating strategy to set the initial substrate concentration equal to the feed concentration \(S_0 = S_f\). Now how long does it take to get to a product concentration \(P\) = 0.8 g/liter?

Exercise 3

We know now have decided to operate the bioreactor with an initial substrate concentration \(S_0\) = \(S_f\). Now we need to decide how long to run the reactor before shutting down, cleaning, and restarting with a new batch. Assume the turn around time is 4 hours, and productivity is measured as

where \(t\) is time since start of the batch. Modify the dataframe to compute productivity as a function of \(t\), and decide the optimal time to run the batch.