6.3. Open-Loop Optimal Control#

This notebook demonstrates the use of CVXPY for the simulation and computation of open-loop optimal control. The notebook includes a lab exercise.

# Install Pyomo and solvers for Google Colab

import sys

if "google.colab" in sys.modules:

!wget -N -q https://raw.githubusercontent.com/jckantor/MO-book/main/tools/install_on_colab.py

%run install_on_colab.py

import numpy as np

import matplotlib.pyplot as plt

6.3.1. Heater Model#

6.3.1.1. Model#

We will use the two-state model for a single heater/sensor assembly for the calculations that follow.

# parameter estimates.

alpha = 0.00016 # watts / (units P * percent U1)

P = 200 # P units

Ua = 0.050 # heat transfer coefficient from heater to environment

CpH = 2.2 # heat capacity of the heater (J/deg C)

CpS = 1.9 # heat capacity of the sensor (J/deg C)

Ub = 0.021 # heat transfer coefficient from heater to sensor

Tamb = 21.0 # ambient temperature

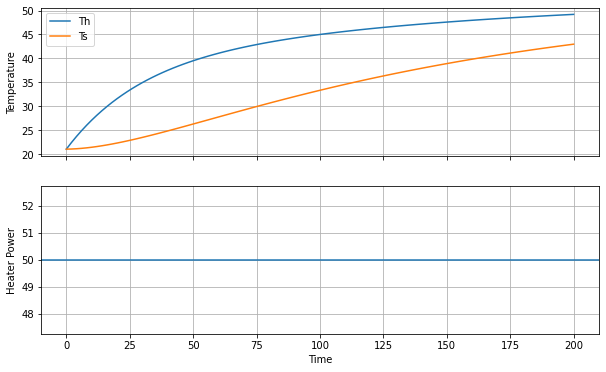

6.3.2. Simulation#

Let’s establish a goal of bringing the heater temperature to 60 deg C. Let’s see how well an initial guess at a control strategy will work for us subject to initial conditions

tf = 200

u = 50.0

import pyomo.environ as pyo

import pyomo.dae as dae

m = pyo.ConcreteModel('TCLab Heater/Sensor')

m.t = dae.ContinuousSet(bounds=(0, tf))

m.Th = pyo.Var(m.t)

m.Ts = pyo.Var(m.t)

m.dTh = dae.DerivativeVar(m.Th)

m.dTs = dae.DerivativeVar(m.Ts)

@m.Constraint(m.t)

def heater1(m, t):

return CpH * m.dTh[t] == Ua *(Tamb - m.Th[t]) + Ub*(m.Ts[t] - m.Th[t]) + alpha*P*u

@m.Constraint(m.t)

def sensor1(m, t):

return CpS * m.dTs[t] == Ub *(m.Th[t] - m.Ts[t])

m.Th[0].fix(Tamb)

m.Ts[0].fix(Tamb)

pyo.TransformationFactory('dae.finite_difference').apply_to(m, nfe=100, wrt=m.t)

pyo.SolverFactory('ipopt').solve(m)

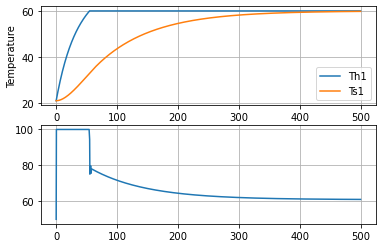

fig, ax = plt.subplots(2, 1, figsize=(10, 6), sharex=True)

ax[0].plot(m.t, [m.Th[t]() for t in m.t], label="Th")

ax[0].plot(m.t, [m.Ts[t]() for t in m.t], label="Ts")

ax[0].legend()

ax[0].set_ylabel("Temperature")

ax[0].grid()

ax[1].axhline(u, label="Power")

ax[1].set_xlabel("Time")

ax[1].set_ylabel("Heater Power")

ax[1].grid()

6.3.3. Exercises#

How well did our guess work? Try different guesses and find a value for \(u\) that results in a heater temperature close to the target of 60 deg C.

What is the impact of simulation time? Is the value determine in question 1 an answer for the power required for a steady state of 60 deg C.

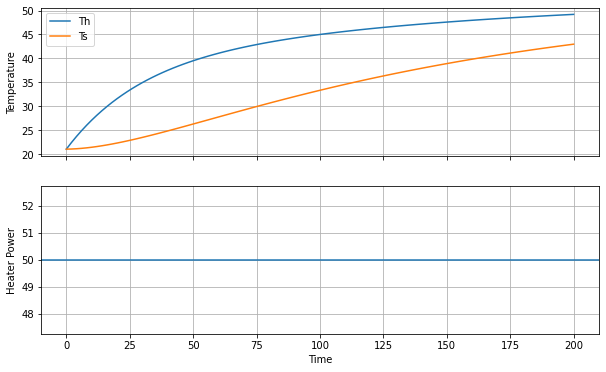

6.3.4. Control to a Target#

How can we set a target value for \(T_h\)?

What are the

additional decision variable(s)?

what are the additional constraints?

what is the objective?

how to modify the Pyomo model?

how to modify the visualization?

tf = 200

u = 50.0

# Modify this code to find a u so that Th(T_final) = 60.

import pyomo.environ as pyo

import pyomo.dae as dae

m = pyo.ConcreteModel('TCLab Heater/Sensor')

m.t = dae.ContinuousSet(bounds=(0, tf))

m.Th = pyo.Var(m.t)

m.Ts = pyo.Var(m.t)

m.dTh = dae.DerivativeVar(m.Th)

m.dTs = dae.DerivativeVar(m.Ts)

@m.Constraint(m.t)

def heater1(m, t):

return CpH * m.dTh[t] == Ua *(Tamb - m.Th[t]) + Ub*(m.Ts[t] - m.Th[t]) + alpha*P*u

@m.Constraint(m.t)

def sensor1(m, t):

return CpS * m.dTs[t] == Ub *(m.Th[t] - m.Ts[t])

m.Th[0].fix(Tamb)

m.Ts[0].fix(Tamb)

pyo.TransformationFactory('dae.finite_difference').apply_to(m, nfe=100, wrt=m.t)

pyo.SolverFactory('ipopt').solve(m)

fig, ax = plt.subplots(2, 1, figsize=(10, 6), sharex=True)

ax[0].plot(m.t, [m.Th[t]() for t in m.t], label="Th")

ax[0].plot(m.t, [m.Ts[t]() for t in m.t], label="Ts")

ax[0].legend()

ax[0].set_ylabel("Temperature")

ax[0].grid()

ax[1].axhline(u, label="Power")

ax[1].set_xlabel("Time")

ax[1].set_ylabel("Heater Power")

ax[1].grid()

6.3.5. Feedforward Optimal Control#

An optimal control policy minimizes the differences

subject to constraints

and prior knowledge of \(d(t)\). Note that pyomo.dae has an Integral object to help with these situations.

import pyomo.environ as pyo

import pyomo.dae as dae

SP = 60.0

tf = 500.0

m = pyo.ConcreteModel('TCLab Heater/Sensor')

m.t = dae.ContinuousSet(bounds=(0, tf))

m.Th1 = pyo.Var(m.t)

m.Ts1 = pyo.Var(m.t)

m.u1 = pyo.Var(m.t, bounds=(0, 100))

m.dTh1 = dae.DerivativeVar(m.Th1)

m.dTs1 = dae.DerivativeVar(m.Ts1)

@m.Integral(m.t)

def ise(m, t):

return (SP - m.Th1[t])**2

@m.Constraint(m.t)

def heater1(m, t):

return CpH * m.dTh1[t] == Ua *(Tamb - m.Th1[t]) + Ub*(m.Ts1[t] - m.Th1[t]) + alpha*P*m.u1[t]

@m.Constraint(m.t)

def sensor1(m, t):

return CpS * m.dTs1[t] == Ub *(m.Th1[t] - m.Ts1[t])

m.Th1[0].fix(Tamb)

m.Ts1[0].fix(Tamb)

@m.Objective(sense=pyo.minimize)

def objective(m):

return m.ise

pyo.TransformationFactory('dae.collocation').apply_to(m, nfe=200, wrt=m.t)

pyo.SolverFactory('ipopt').solve(m)

fig, ax = plt.subplots(2, 1)

ax[0].plot(m.t, [m.Th1[t]() for t in m.t], label="Th1")

ax[0].plot(m.t, [m.Ts1[t]() for t in m.t], label="Ts1")

ax[0].legend()

ax[0].set_xlabel("Time")

ax[0].set_ylabel("Temperature")

ax[0].grid()

ax[1].plot(m.t, [m.u1[t]() for t in m.t], label="U1")

ax[1].grid()

6.3.6. Controlling to a Reference Tractory#

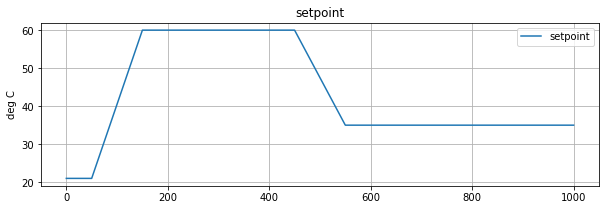

The reference trajectory is a sequence of ramp/soak intervals. Python function r(t) uses numpy.interp to compute values of the reference trajectory at any point in time.

# time grid

tf = 1000

dt = 2

n = round(tf/dt)

t_grid = np.linspace(0, 1000, n+1)

# ambient temperature

Tamb = 21

# setpoint/reference

def r(t):

return np.interp(t, [0, 50, 150, 450, 550], [Tamb, Tamb, 60, 60, 35])

# plot function

fig, ax = plt.subplots(1, 1, figsize=(10, 3))

ax.plot(t_grid, r(t_grid), label="setpoint")

ax.set_title('setpoint')

ax.set_ylabel('deg C')

ax.legend()

ax.grid(True)

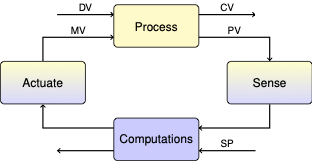

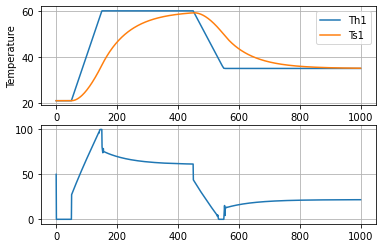

6.3.7. The Control Problem#

For the purposes of this notebook, the control problem is to find a control policy \(u(t)\) for the interval \(0 \leq t \leq t_f\) which causes the output \(y(t)\) to track a desired setpoint or reference tracjectory \(r(t)\).

import pyomo.environ as pyo

import pyomo.dae as dae

SP = 60.0

tf = 1000.0

m = pyo.ConcreteModel('TCLab Heater/Sensor')

m.t = dae.ContinuousSet(bounds=(0, tf))

m.Th1 = pyo.Var(m.t)

m.Ts1 = pyo.Var(m.t)

m.u1 = pyo.Var(m.t, bounds=(0, 100))

m.dTh1 = dae.DerivativeVar(m.Th1)

m.dTs1 = dae.DerivativeVar(m.Ts1)

@m.Integral(m.t)

def ise(m, t):

return (r(t) - m.Th1[t])**2

@m.Constraint(m.t)

def heater1(m, t):

return CpH * m.dTh1[t] == Ua *(Tamb - m.Th1[t]) + Ub*(m.Ts1[t] - m.Th1[t]) + alpha*P*m.u1[t]

@m.Constraint(m.t)

def sensor1(m, t):

return CpS * m.dTs1[t] == Ub *(m.Th1[t] - m.Ts1[t])

m.Th1[0].fix(Tamb)

m.Ts1[0].fix(Tamb)

@m.Objective(sense=pyo.minimize)

def objective(m):

return m.ise

pyo.TransformationFactory('dae.collocation').apply_to(m, nfe=200, wrt=m.t)

pyo.SolverFactory('ipopt').solve(m)

fig, ax = plt.subplots(2, 1)

ax[0].plot(m.t, [m.Th1[t]() for t in m.t], label="Th1")

ax[0].plot(m.t, [m.Ts1[t]() for t in m.t], label="Ts1")

ax[0].legend()

ax[0].set_xlabel("Time")

ax[0].set_ylabel("Temperature")

ax[0].grid()

ax[1].plot(m.t, [m.u1[t]() for t in m.t], label="U1")

ax[1].grid()

Study Question: Evaluate how well this control policy performed. Keep in mind that the objective is for \(T_S\) to track the reference input (i.e., the setpoint) as closely as possible. Did the controller achieve the desired steady-state? What about the prior ramp and soak periods?

Study Question: Edit the cells above to change \(u(t)\) in to produce a response closer to the target. Make at least 3 attempts. What changes did you make, and were you able to get a better result.

Study Question: What criteria could you use to determine if one control policy was better than another? Give at least three examples of possible criteria.

Study Question: The optimal control computed above requires rapid changes in power level. In process systems where control action requires movement of a valve stem position, there are often limits on how fast the manipulated variable can change. Modify the model to include differential inequalities that limit the time rate of change of control.

where \(\dot{u}_{max}\) is the maximum rate of change. Add these rate constraints to the problem above. Specify that the maximum power cannot change more than 1% per second.

How does that change the response?

Study Question: Change the objective so that the goal is to guide the heater (insteady of the sensor) temperature to the reference trajectory. How does the control policy change? Explain what you observe.